Sustainability

Our primary product – paper honeycomb – is based on 100% recyclable paper and often serves as a substitution for solid or oil-based materials.

Especially in the packaging industry, which has a high percentage of single-use and disposable products, paper honeycomb is a great alternative to oil-based packaging such as EPS. For now, many areas still have the choice between EPS and paper based materials, but expanding legislation is rapidly moving towards paper-based products.

In the Construction and Furniture industries, paper honeycomb is often substituted for solid wood products. Due to it’s open-cell structure, it can reduce the paper / pulp requirements by 95%, preventing deforestation.

Not only is the material itself more sustainable than alternatives, it also indirectly adds sustainability to the end product. For example, a traditional car hood weighs around 27kg, while the same hood made with paper honeycomb core technology weighs only 7kg – a 74% reduction. This translates into lower wear on other vehicle components such as tires and higher energy / fuel efficiency.

At Axxor, sustainability is part of our mission and is woven into our way or working. As a global leader in the production of paper honeycomb, together with our customers, we help drive sustainability all around the world.

Benefits

Paper

Paper is the primary raw material for paper honeycomb production. It is a natural product that is readily available all around the world. Within our production in Europe, we only process 100% recycled paper.

Compared to alternative core materials such as foam and honeycomb materials based on PVC and aluminum, paper honeycomb has the smallest ecological footprint.

Glue

Depending on the process and end product requirements of our customer, we can leverage different types of adhesives. For example, for relatively 2D applications we can utilize a compression strength enhancing adhesive, or for a 3D application we might use a more flexible one, or we can offer adhesives suitable for high processing temperatures.

In all cases, we only use water based PVAc glues, which are biodegradable dispersion glues that use environmentally friendly components.

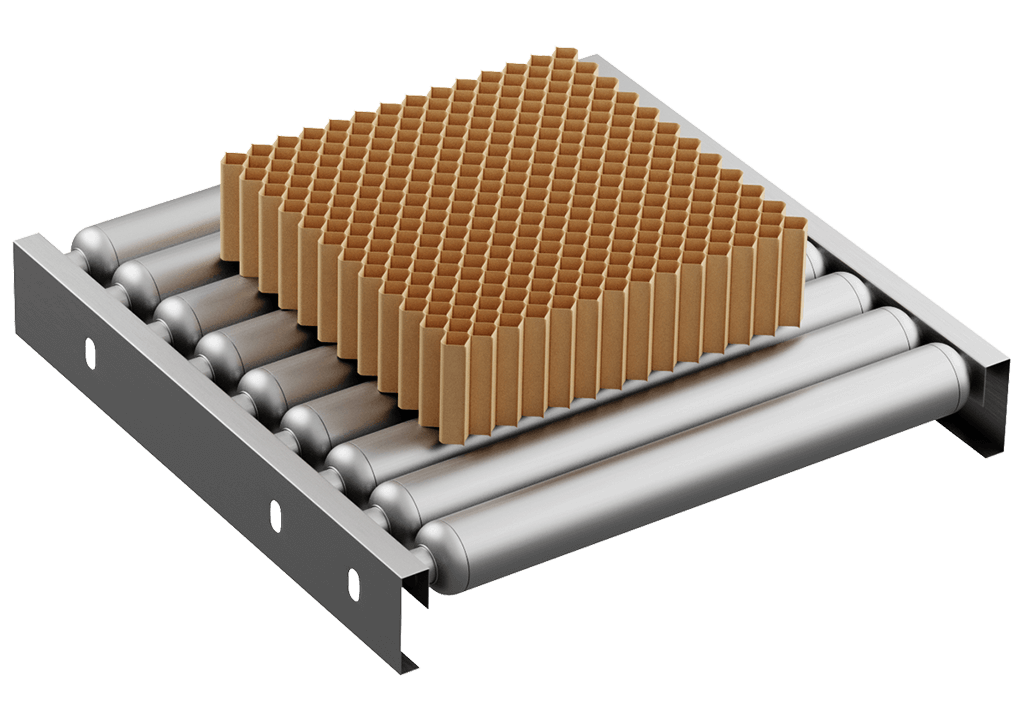

Waste reduction

Our many quality certifications, in particular our ISO 14001 certification, attest that our quality management system is designed to reduce the amount of waste in every process.

Any paper honeycomb waste generated during our manufacturing process is then returned to the paper industry, where it can be recycled and used again.

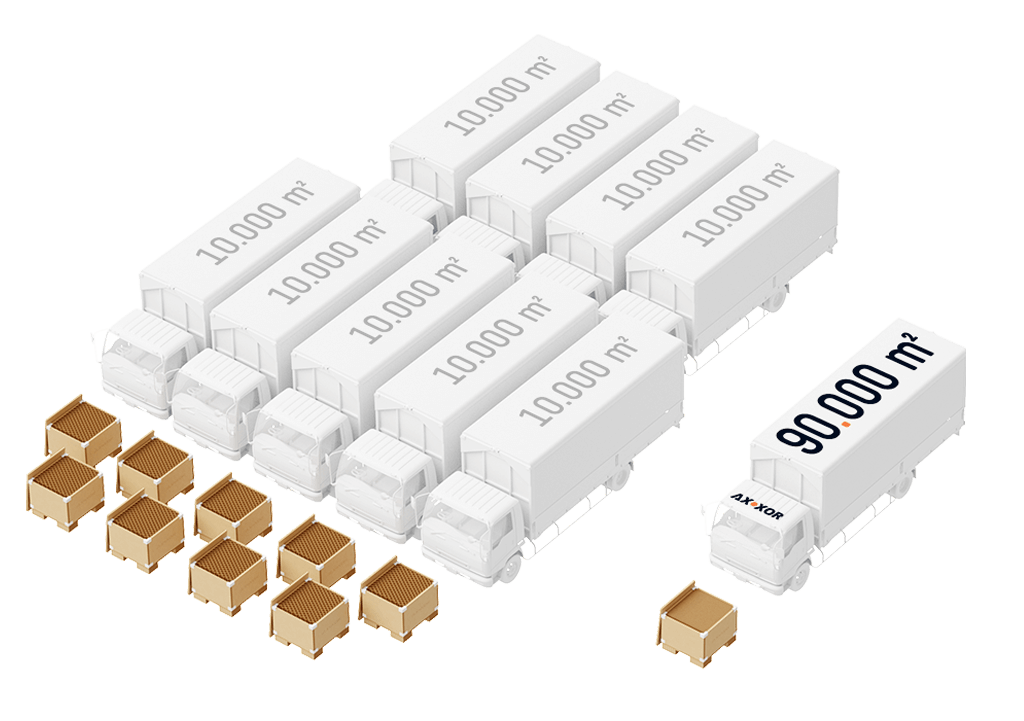

Efficient transport

Our products can be shipped with the cells closed, eliminating up to 90% of the transport and inventory requirements. In addition, our multi-continent manufacturing footprint allows us to start closer to our customer base.

Sustainable packaging solutions

Not only is our product sustainable, in many cases we can provide our product in tailor-made packaging that reduces the material required and lowers costs.

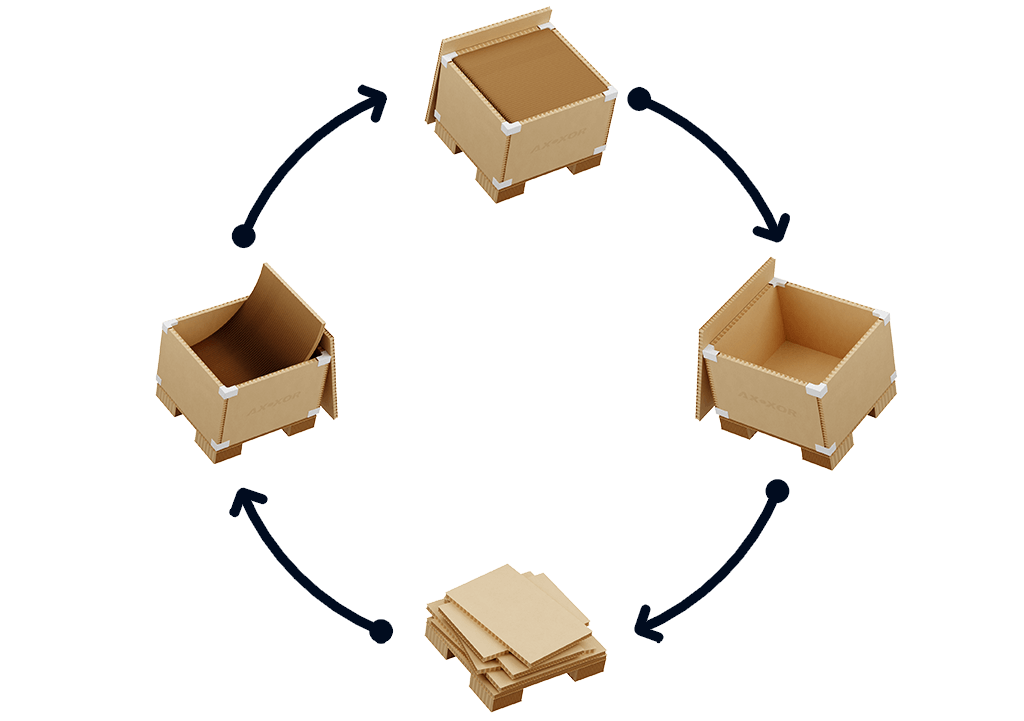

When the situation permits, we can leverage returnable packaging. For example, extremely strong pallets made from recycled materials or pallet boxes can be returned to use for multiple uses.

Energy

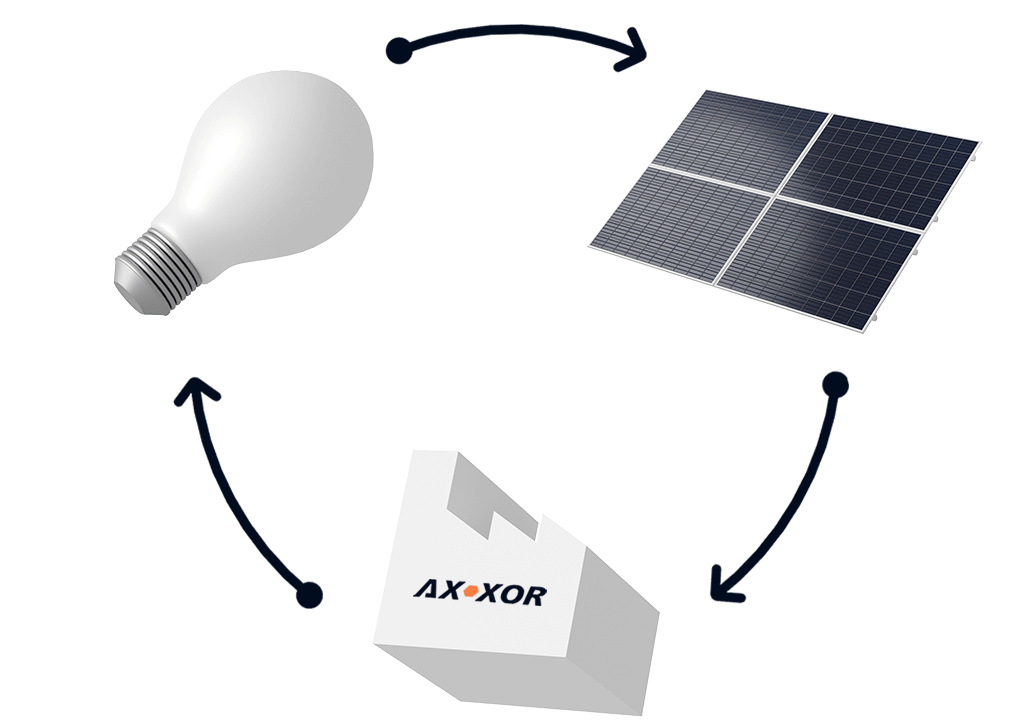

Axxor also strives to make our production solutions as energy efficient as possible.

Our locations are fully equipped with LED lighting, which also promotes human safety. Generating our own electricity with solar panels is also part of our strategy.

Our ambition for our new production location is to further reduce our energy requirements and to be 100% self-sufficient.

Quality marks

Since paper is the most important raw material for our honeycomb, we attach great importance to our FSC® certification registered under number FSC®-C089393. We therefore only use FSC® certified paper in our honeycomb products that are produced in Europe.

Further demonstrating our commitment to the environment, our ISO 14001 certification (Axxor Holding, Axxor Industry The Netherlands and Axxor B.V.) provides assurance of our effective environment management system. Some particular aspects of this EMS include life cycle analysis and how we address environmental challenges like climate change.

All Axxor locations can use 100% recycled paper for the production of paper honeycomb and it is the only type of paper used at our European production facilities. Since it uses paper waste that would otherwise go to landfills and is 100% recyclable after usage, this builds the circular economy. In addition, it saves greenhouse gas (GHG) emissions, waste, net energy, and trees.