When people in the industry talk about paper honeycomb cell size, they often assume it refers to the exact diameter of a honeycomb cell. In some materials such as Nomex® or plastic honeycomb, this is indeed the case. For these honeycomb cores, cell size is standardized and directly linked to the inner or outer diameter of the cell. For paper honeycomb core, this works differently. There are no industry standard cell sizes (yet!) for paper honeycomb.

How paper honeycomb is made

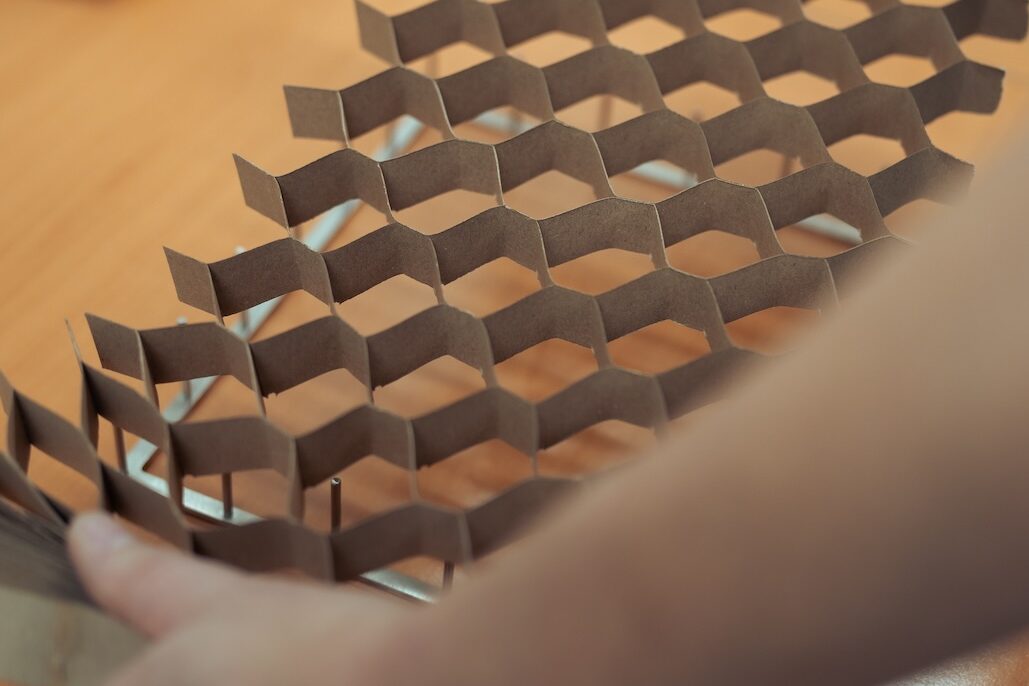

Paper honeycomb core is produced by gluing together sheets of paper and is mostly transported in unexpanded form. This makes paper honeycomb core flexible and efficient to produce, but it also means that the actual size of a cell depends on several variables in both production and further processing.

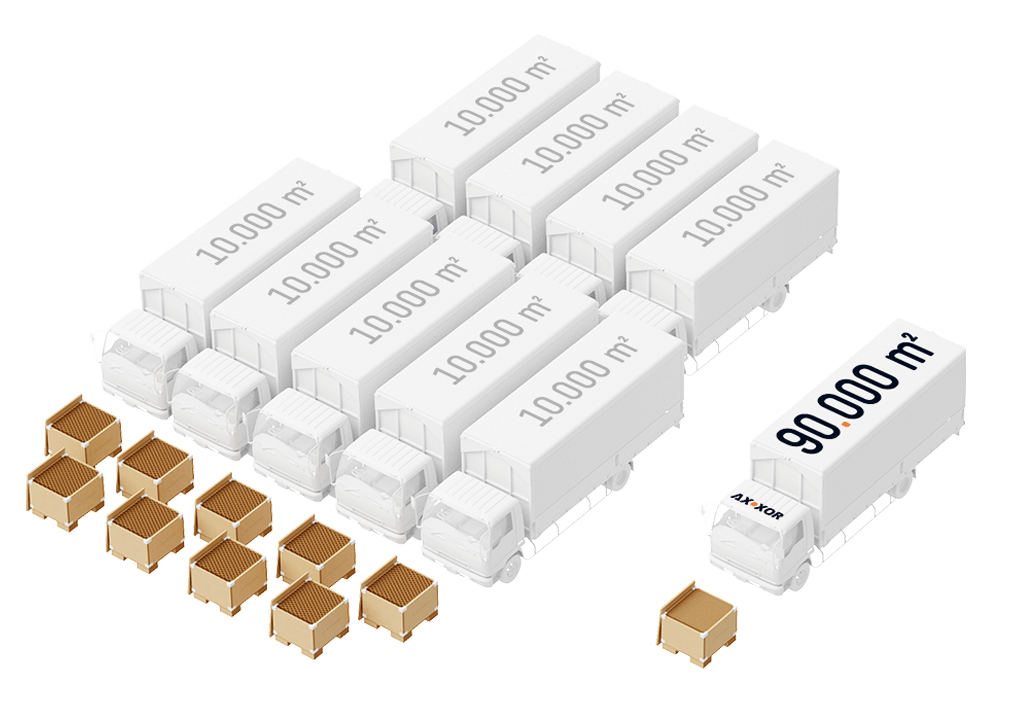

Learn more about the benefits of shipping unexpanded paper honeycomb

Because paper honeycomb is shipped in an unexpanded form, large volumes can be stacked into a single truck. This allows many square meters of material to be delivered at low transportation cost and with reduced environmental impact. At the customer’s facility, the honeycomb is expanded and shaped to the required dimensions, ensuring flexibility and efficiency in use.

What defines the size of a cell in paper honeycomb

In its unexpanded form, paper honeycomb core can be seen as a series of paper sheets connected by a specific glue pattern. The size of a cell is determined by two main factors: the width of the glue lines that bond the sheets together, and the distance between those glue lines (known as the pitch).

Glue line width

Glue lines form the backbone of the honeycomb cell structure. Their width and placement determine how the paper layers bond during expansion. Applications that require higher strength often use wider glue lines, while lightweight applications benefit from thinner glue lines to maximize efficiency.

Pitch

Pitch is the distance between every second glue line in the unexpanded honeycomb. Why every second glue line? In production, two alternating glue patterns are applied, often referred to as the A and B pattern. When these patterns are repeated, they form the recognizable cell structure. A smaller pitch results in smaller cells, while a larger pitch creates larger structures.

Why cell size in honeycomb is just a name

When we use the name “Cell size 12”, this refers to a cell design created by a specific combination of glue line width and pitch. The number 12 suggests that the diameter of the cell is about 12 mm, but in reality the surface of the cell may be significantly larger or smaller. In other words: it is just a convenient name, not an exact measurement.

What to look for instead: the cell indicator and surface area

To make comparisons more accurate, the paper honeycomb industry association EMPHA introduced the Cell Indicator (CI). This is a geometry-based number that provides a more reliable reference than cell size. The cell indicator represents the distance between two glue lines in the machine direction at 75% expansion of the core. In practice, it tells you how the cell is built and how it will behave.

Another useful way to look at a honeycomb cell is its surface area at 75% expansion. This surface area can be expressed in mm² per cell or per unit of mass. It helps determine the material yield you get from a certain configuration. Keep in mind that the actual surface area will still vary depending on how much the core is expanded during processing.

At Axxor, when we refer to a certain cell size, it is therefore not meant as the exact diameter of the cell. Instead, it is a practical way to classify different types of honeycomb, while the true performance is defined by pitch, glue line width, expansion ratio, and the cell indicator.

Using the right honeycomb core cell size

Selecting the right cell size is about more than just geometry. It influences strength, weight, efficiency in production, and even environmental impact. Smaller cells can improve structural integrity, while larger cells often provide advantages in reducing weight and cost. The right choice always depends on the balance between performance requirements and material efficiency.

With more than 25 years of expertise, Axxor supports customers in identifying and implementing the optimal honeycomb core products for their specific applications in automotive, furniture, packaging, and construction industries.

Examples from packaging and automotive

In the packaging industry, cell size can make a major difference. A smaller cell size honeycomb provides higher strength and protection, which is ideal for packaging heavy or fragile goods. Larger cells, on the other hand, are often sufficient for lighter products and help reduce material use and costs.

In automotive applications, the honeycomb core is typically optimized for weight reduction without sacrificing stiffness. This supports sustainability goals by lowering fuel consumption and reducing emissions. Each industry requires its own balance between performance and efficiency, which is why expertise in selecting the right configuration is so valuable.

Conclusion: understanding the honeycomb cell structure

In paper honeycomb, cell size is best understood as a name rather than a fixed measurement. The true performance of the core depends on the combination of pitch, glue line width, and expansion ratio. Together these parameters define how the honeycomb behaves in real applications. The cell indicator is a practical tool to describe and compare different cell designs, but it should be seen as an indication rather than a direct measure of performance.

Axxor’s engineers are ready to guide customers in selecting the right core products and configurations to achieve the best balance of strength, weight, sustainability, and cost efficiency.

Was this article helpful?