Certifications

Our way to test ourselves and continually improve

Certifications are a way for us to continually test and improve upon our values and standards with regards to sustainability, social and working conditions, animal welfare, quality management and business continuity.

ISO 9001 is a globally recognized quality management standard and therefore a benchmark for transparency and reliability in the market. This certification ensures that quality management is reflected in all parts and processes in the organization. Through this, Axxor demonstrates that our quality management is well managed and meets the needs, requirements, wishes and specifications of customers and other stakeholders.

With the IATF 16949 certification in hand for Axxor NA, we show that we are leveraging a process oriented quality management system, providing for continual improvement, defect prevention and reduction of variation and waste in the supply chain. This allows us to meet automotive industry customer requirements efficiently and effectively.

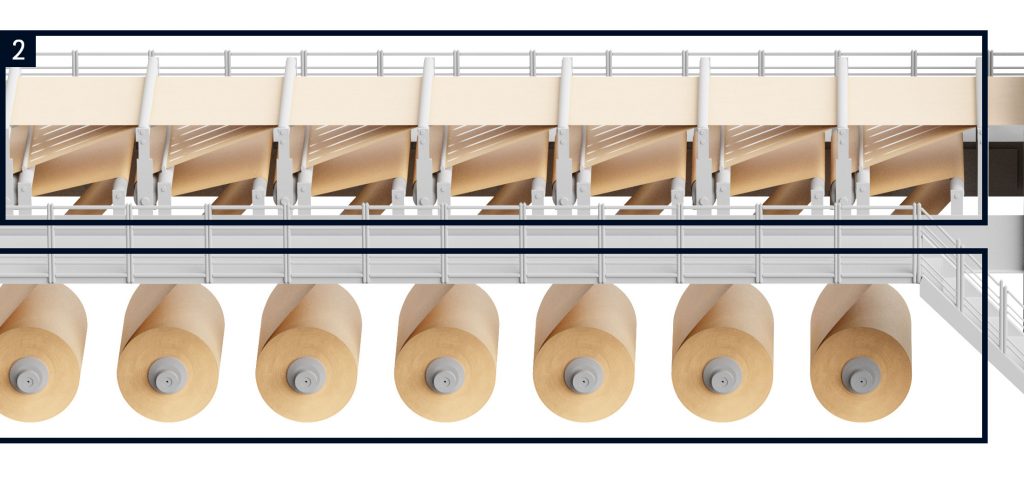

Since paper is the most important raw material for our honeycomb, we attach great importance to our FSC® certification registered under number FSC®-C089393. We therefore only use FSC® certified paper in our honeycomb products that are produced in Europe.

Further demonstrating our commitment to the environment, our ISO 14001 certification provides assurance of our effective environment management system. Some particular aspects of this EMS include life cycle analysis and how we address environmental challenges like climate change.

All Axxor locations can use 100% recycled paper for the production of paper honeycomb and it is the only type of paper used at our European production facilities. Since it uses paper waste that would otherwise go to landfills and is 100% recyclable after usage, this builds the circular economy. In addition, it saves greenhouse gas (GHG) emissions, waste, net energy, and trees.

IWAY is the IKEA supplier code of conduct for responsibly sourcing products, services, materials and components. It sets clear expectations for environmental, social and working conditions, as well as animal welfare.

The NIS2 Directive is European legislation designed to strengthen the level of cybersecurity across the EU. Organisations in essential and important sectors, such as industry, logistics, energy, and digital services, must demonstrate increased digital resilience by managing risks, implementing appropriate security measures, and reporting incidents in a timely manner. Axxor Holding complies with this directive and applies the NIS2 principles as part of its daily operations. This not only strengthens our own security and continuity, but also that of our customers and partners. Security, reliability, and transparency form the foundation of how we work.

In industries like automotive, packaging, and construction, where timing and reliability are everything, these factors can make the difference between meeting a production deadline or falling behind. With ISO 28000, we ensure that security isn’t a weak link in your supply chain.