Our products

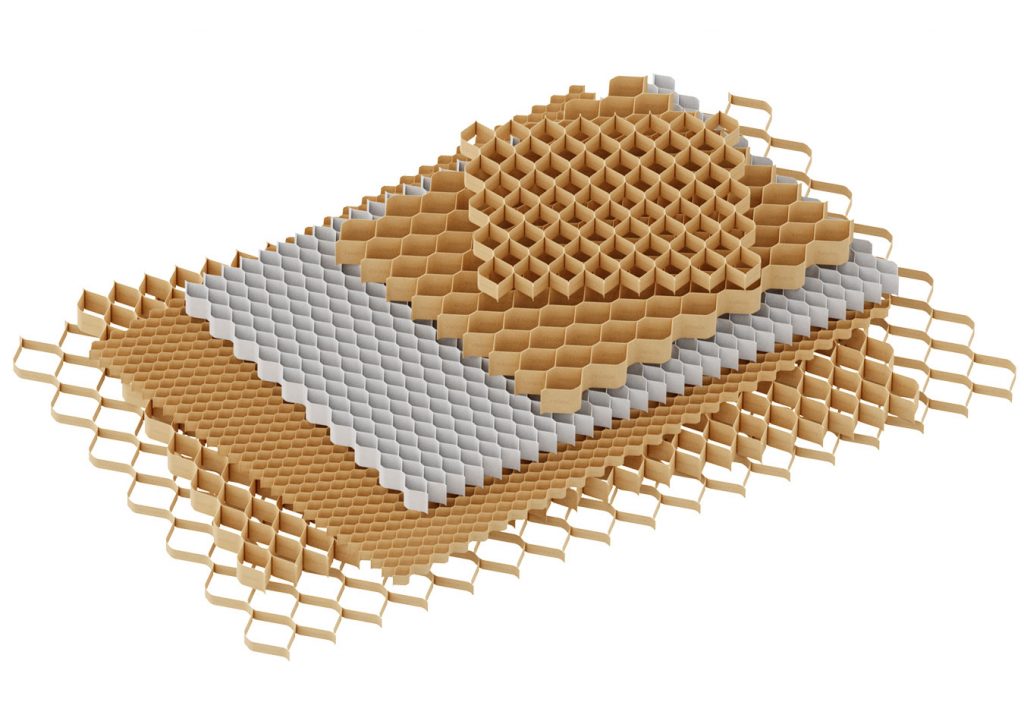

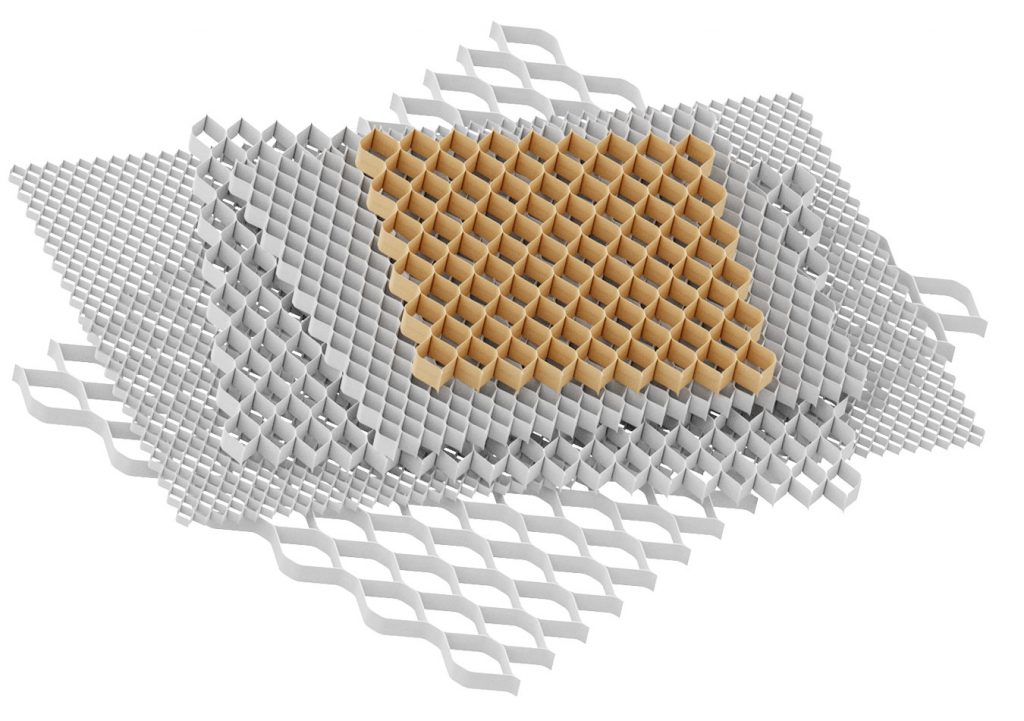

Axxor produces a wide range of paper honeycomb core products, based on different paper types, cell configurations, heights and widths.

Europe & Global

RAW materials

| Tolerance | Unit | Norm | ||

| Paper Types | AxCore, TL, RG, KL | |||

| Paper Certifications | 100% FSC | |||

| Paper Weights | 80 – 300 | ±5 | gsm / m2 | ISO 536 |

| Paper Widths | 800 – 2800 | +5/-0 | mm | ISO 536 |

| Glue | PVAC | |||

| Glue Types | High compression | |||

| HEAT resistant |

Paper honeycomb core

| Tolerance | Unit | Norm | ||

| Cell Names | 6 – 41.1 | |||

| Pitches | 8 – 108 | ±5 | G / m2 | EMPHA |

| Glue Line Widths | 2.6 – 20.0 | + 1,0 / – 1,5 | mm | EMPHA |

| Core Height | 5-150 | ± 0,2 | mm | EMPHA |

| Core Width Unexpanded | 200 – 2800 | ± 10 | mm | ISO 536 |

| Core Width Expanded | 150 – 2100 | ± 10 | mm | ISO 536 |

| Core Lengths | Functionally Endless, Limited by Specification & Pallet Capacity | |||

| Compression at 4% | 20 – 1500 | ± 15% | kPa | ISO 287 |

| Expansion Rate | 75.0 | % | EMPHA | |

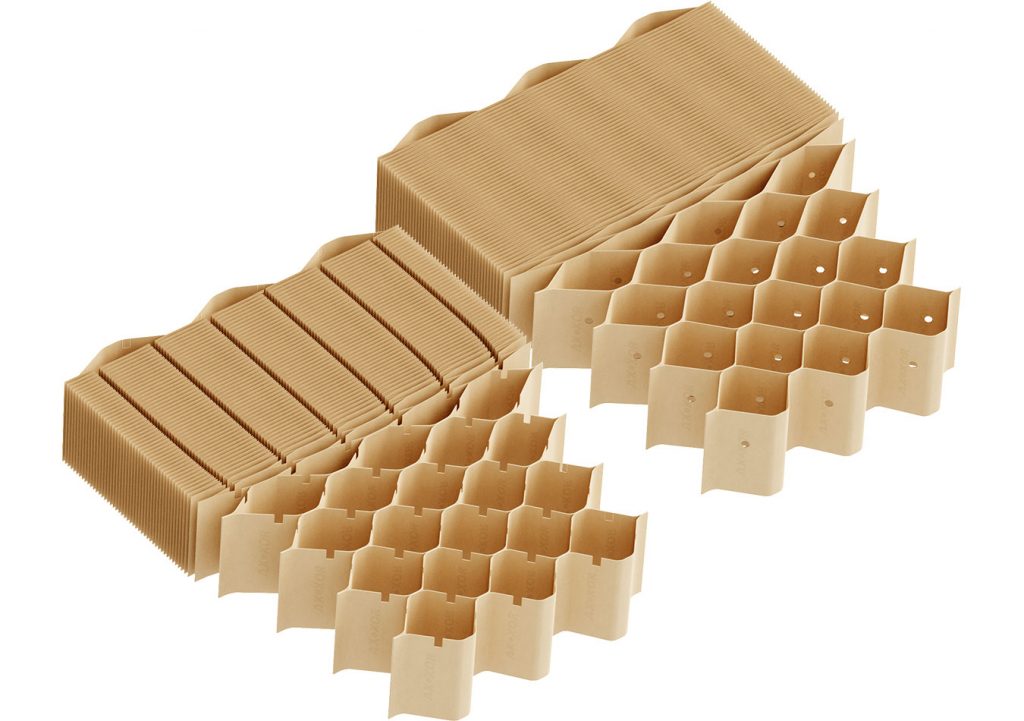

Optional perforation or ventilation

Axxor realizes the details matter, such as how hot pressing operations can cause defects in the finished panel if air movement is not considered. For this reason, Axxor developed the capability to produce honeycomb in a way that allows air to move between the cells, preventing these defects.

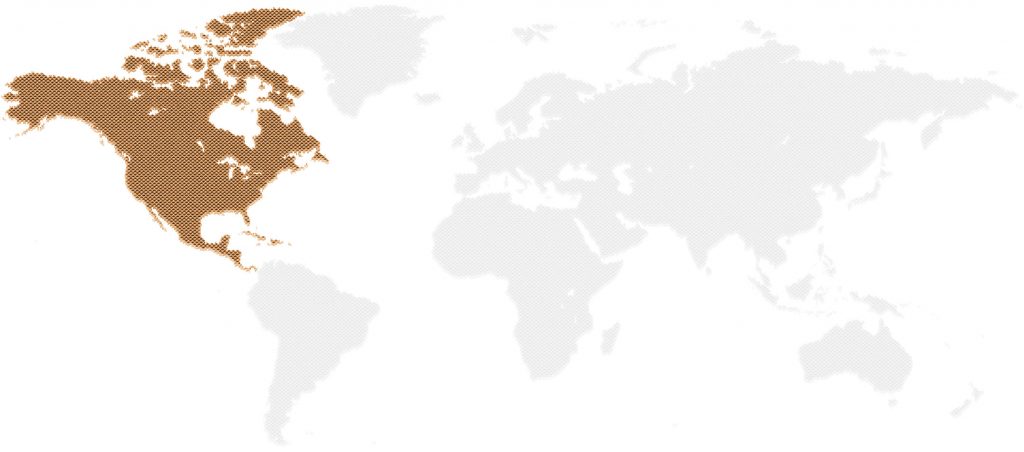

North America

RAW materials

| Tolerance | Unit | Norm | ||

| Paper types | Virgin, Recycled, Blend, White | |||

| Paper Certifications | SFI, FSC | |||

| Paper Weights | 80 – 200 | ±5 | gsm / m2 | ISO 536 |

| Paper Widths | 560 – 2800 | +5/-0 | mm | ISO 536 |

| Glue | PVAC | |||

Paper honeycomb core

| Tolerance | Unit | Norm | ||

| Cell names | 6 – 32 | |||

| Pitches | 12 – 68 | ±5 | G / m2 | EMPHA |

| Glue Line widths | 3.0 – 10.0 | + 1,0 / – 1,5 | mm | EMPHA |

| Core Height | 4.8 – 150.0 | ± 0,2 | mm | EMPHA |

| Core Lengths | Functionally Endless, Limited by Specification & Pallet Capacity | |||

| Compression at 4% | 5 – 175 (35 – 1200) | ± 15% | psi (kPa) | ISO 287 |

Optional perforation

Axxor realizes the details matter, such as how hot pressing operations can cause defects in the finished panel if air movement is not considered. For this reason, Axxor developed the capability to produce honeycomb in a way that allows air to move between the cells, preventing these defects.

KITS

In addition to unexpanded honeycomb core, Axxor NA also offers honeycomb composite kits, consisting of pre-expanded honeycomb faced with roll stock (e.g. fiberglass) or board form (e.g. Polypropylene Glass Fiber or GMT) skin materials.

Kits are ready for thermoforming or PUR-CSM processing.

Want to start your program with kits but later vertically integrate and bring more value-add internally? No problem – Axxor can assist with both.